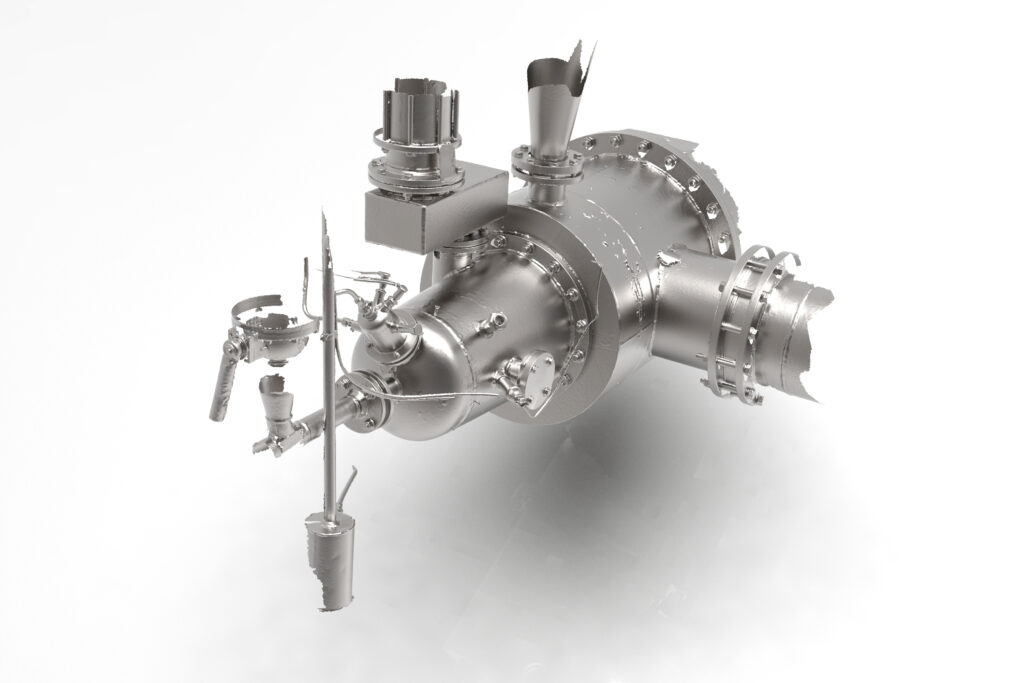

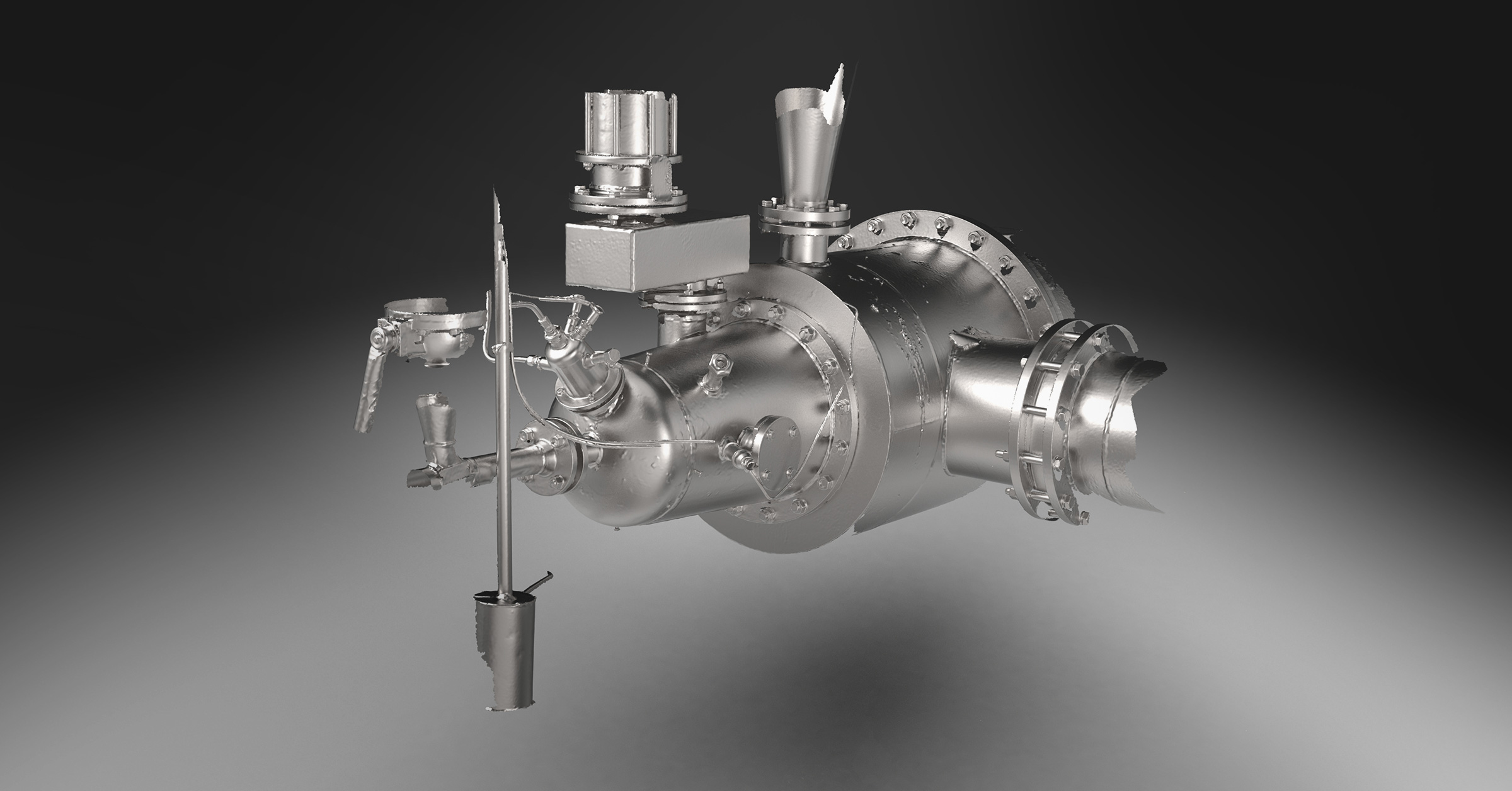

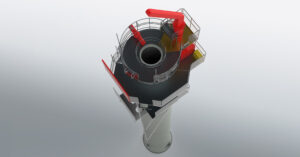

SITE was tasked with 3D-scanning an old burner in order to use reverse engineering to manufacture a new, updated burner for the coking plant at SSAB Luleå.

Our role: 3D scanning, management, construction

Consultant: Erik Renman

About the project

A burner at the coking plant is starting to wear out and the customer SSAB Luleå wants to replace parts as part of the preventive maintenance. The problem is that this component is old and so is the drawing material, which over time has become inadequate for today’s construction.

Our mission was to high-precision scan the existing burner with a 3D scanner and then, using reverse engineering, create a new model with modern manufacturing materials for a new, slightly improved variant of the burner.

With its hand-held scanner, SITE can relatively quickly produce a 3D scan with high precision, which can then be used when modeling an object.

Pictures